Antioxidationsmittel TNP CAS 26523-78-4

Chemischer Name: Tris(nonylphenyl) phosphite

Synonyme Bezeichnungen: 4-nonyl-phenol phosphite

IRGAFOS TNPP

CAS-NR: 26523-78-4

3050-88-2

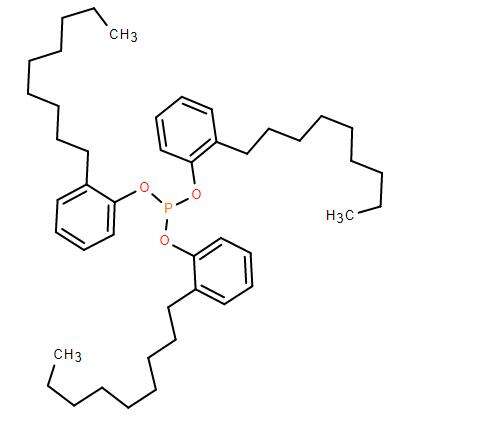

Molekülformel: C45H69O3P

Erscheinungsbild: farblos oder hellgelbe, transparente zähflüssige Flüssigkeit

Molekülmasse: 689

EINECS: 247-759-6

- Parameter

- Verwandte Produkte

- Anfrage

Strukturformel:

Beschreibung des Produkts:

| Index | TECHNISCHE DATEN |

| Erscheinung | farblos oder hellgelbe, transparente zähflüssige Flüssigkeit |

| Viskosität, mPa.s | 15°C~15000cps 25°C~6000cps 40°C~1300cps 50°C~525cps 55°C~395cps 60°C~250cps 70°C~115cps 80°C~80cps 90°C~50cps 100°C~32cps |

| APHA(Pt-Co) | Nicht mehr als 250 |

| Säurezahl (mgKOH/g) | Nicht mehr als 0,3 |

| Dichte | 0.979—0.992 |

| Brechungsindex(n25D) | 1,5230—1,5280 |

Antioxidationsmittel TNP ist ein effizientes, umweltfreundliches, hitzebeständiges Antioxidationsmittel, das in der Gummischleif- und Kunststoffindustrie weit verbreitet wird, insbesondere für synthetisches Gummi, Naturkautschuk und verschiedene Polyolefin-Kunststoffe geeignet. Dieses Produkt kann nicht nur die Wärmebeständigkeit und das Antioxidationsvermögen des Materials verbessern, sondern auch effektiv verhindern, dass sich die Farbe des Produkts während der Verarbeitung und Nutzung ändert. Es ist eine ideale Wahl für weiße und hell gefärbte Produkte.

Hauptmerkmale und Vorteile:

1. Keine Verschmutzung: TNP ist ein verschmutzungsfreies Antioxidationsmittel und hat keinen Einfluss auf die Farbe des Produkts. Es ist besonders für hochwertige Produkte geeignet, die keine Farbänderung erfordern.

2. Hitzebeständigkeit: In der Lage, in Hochtemperaturumgebungen stabil zu bleiben und die Lebensdauer des Produkts zu verlängern.

Verhindert Harzbildung und Gelbwerden: Während der Kautschukverarbeitung kann TNP effektiv Harzbildung und Gelbwerden verhindern und das ästhetische Erscheinungsbild und die Leistungsfähigkeit des Produkts aufrechterhalten.

3. Verbesserung der Lichtstabilität: In Materialien wie Polyvinylchlorid (PVC), Polystyrol (PS), Vinylfluorpolymeren und ABS-Copolymern kann TNP die Lichtstabilität erheblich verbessern und das Verfärben von Alkylphenolen verhindern.

Anwendungsbereich:

1. Synthetischer Kautschuk und Naturkautschuk: Als nicht verfärbender Stabilisator hat TNP keinen Einfluss auf den Vulkangprozess und kann Kautschuk weich halten sowie die Bildung von Gel verhindern.

2. Polyolefin-Plastik: Unter verschiedenen Polyolefin-Plastiken kann TNP effektiv Gelbildung verhindern und die Alterungsbeständigkeit des Materials verbessern.

3. Klebstoff: Durch Hinzufügen von TNP zum Klebstoff kann dessen Haftfähigkeit erhalten und der Schutzeffekt verbessert werden.

Verpackung:

Dieses Produkt wird in galvanisierten Blechdrummen verpackt, Netto-Gewicht 200 kg/Drumme, und kann auch nach Kundenanforderungen angepasst werden.

Lagerbedingungen:

Dieses Produkt sollte in einem trockenen und kühlen Umgebung aufbewahrt werden, vermeiden Sie hohe Temperaturen während der Lagerung und des Transports und achten Sie auf wasserdichte und feuchtigkeitsfreie Bedingungen. Beim Handhaben dieses Produkts vermeiden Sie starkes Reiben, um Schäden an der Verpackung zu verhindern.

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

IW

IW

ID

ID

LV

LV

LT

LT

SR

SR

SK

SK

VI

VI

HU

HU

TH

TH

TR

TR

GA

GA

CY

CY

KA

KA

LA

LA

MN

MN

KK

KK

LB

LB