Zirconium silicate CAS 10101-52-7

Chemical name: Zirconium silicate

Synonymous names:

ZIRCON

acorite

Auerbachite

CAS No: 10101-52-7

EINECS No: 233-252-7

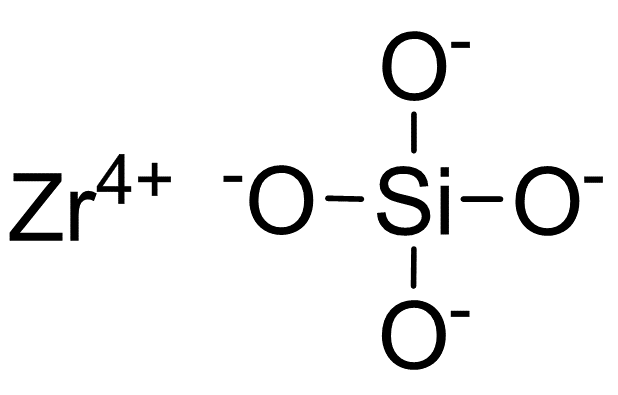

Molecular formula: O4SiZr

Molecular weight: 183.3071

- Parameter

- Related products

- Inquiry

Structural formula:

Product Description:

|

FSCI-Item |

Granularity |

Whiteness |

|

ZrO2 ≥64% |

1.0um Max |

93 |

|

Fe2O3 ≤0.1% |

||

|

TiO2 ≤0.15% |

||

|

SiO2 ≤32% |

Properties and Usage:

Zirconium silicate (CAS 10101-52-7), with the chemical formula ZrSiO4, is a silicate mineral with superior performance.

1. Ceramic Industry

Opacifier: Zirconium silicate is used as an opacifier in ceramic glazes and enamels, giving the ceramic glaze a glossy, opaque white appearance and significantly enhancing its durability. Whether it is architectural ceramics, sanitary ceramics or daily ceramics, zirconium silicate can improve the beauty and durability of the product.

Refractory materials: Zirconium silicate occupies an important position in the production of refractory materials due to its high melting point and excellent thermal stability. It is often used in the lining materials of high-temperature industrial furnaces to ensure stable performance under extreme conditions.

2. Abrasives

Grinding and polishing: Zirconium silicate is an ideal abrasive for grinding and polishing applications due to its hardness and wear resistance. It is suitable for polishing metal, stone and other hard surfaces, ensuring efficient and long-lasting polishing effects.

3. Casting Industry

Casting molds: In the casting industry, zirconium silicate is used to make casting molds and cores for metal casting. It has excellent thermal stability and resistance to metal penetration, ensuring good quality and consistency of castings.

4. Pigments and coatings

Paints and coatings: Zirconium silicate is used as a pigment to enhance the opacity of paints and coatings and improve the durability of the finish. Its excellent chemical stability enables it to maintain excellent performance under various environmental conditions.

5. Glass manufacturing

Emulsifier and strengthener: In the glass manufacturing process, the addition of zirconium silicate can increase the opacity of glass and enhance its mechanical strength. It is widely used in the production of television picture tubes and emulsified glass.

6. Optical materials

Zirconium silicate has good refractive index and optical stability. It can be used to manufacture various optical devices, such as lenses and lenses, to meet high-precision optical needs.

Storage and transportation:

Store in a dark, dry and cool place, and strictly prohibit mixing with toxic and harmful substances.

Packaging specifications:

Net weight 25KG/ bag, or customized packaging according to customer requirements.

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

IW

IW

ID

ID

LV

LV

LT

LT

SR

SR

SK

SK

VI

VI

HU

HU

TH

TH

TR

TR

GA

GA

CY

CY

KA

KA

LA

LA

MN

MN

KK

KK

LB

LB