UV-531 CAS 1843-05-6

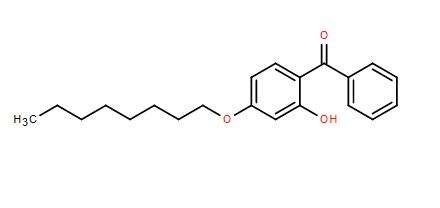

Chemical name:Octabenzone

Synonymous names:CHIMASSORB 81;

BENZOPHENONE-12;

UV Abosorber 531

BP-12

2-Hydroxy-4-n-octyloxy benzophenone

CAS No: 1843-05-6

Molecular formula:C21H26O3

Content:≥99%

Molecular weight:326.432

EINECS: 217-421-2

- Parameter

- Related products

- Inquiry

Structural formula:

Product Description:

| Index | Specifications |

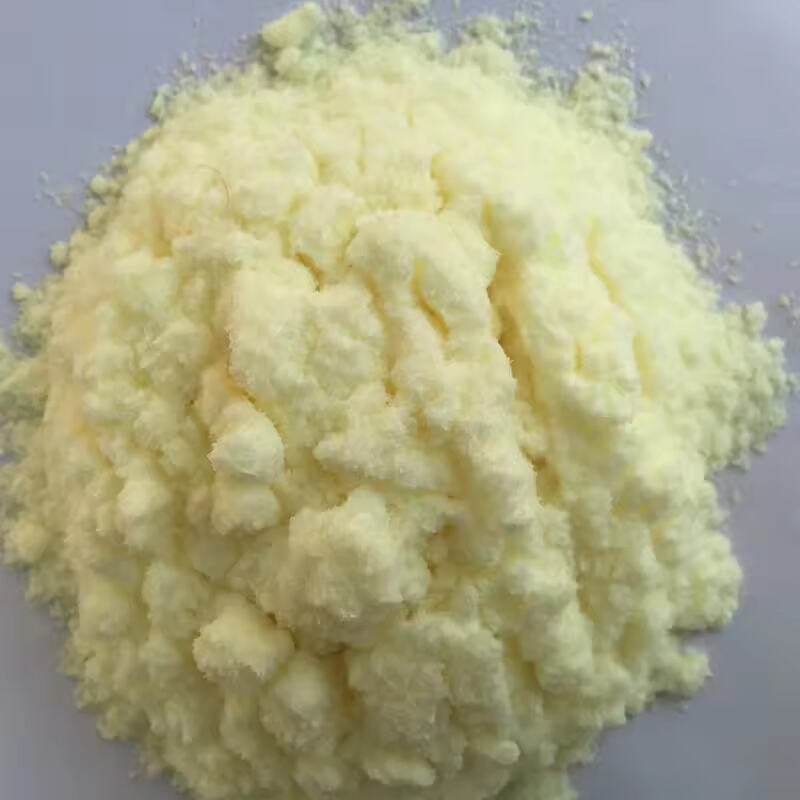

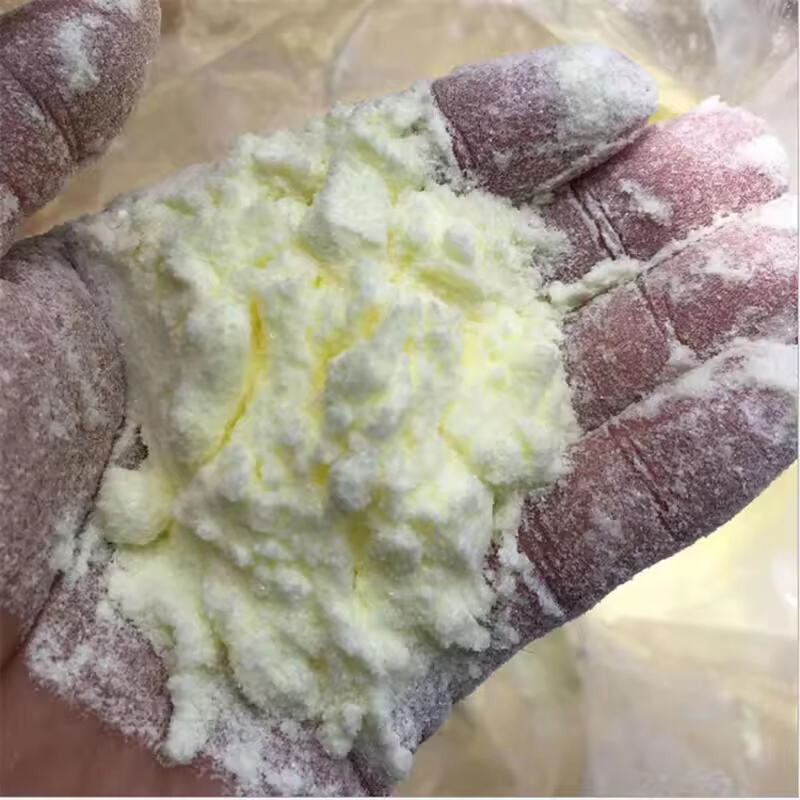

| Appearance | Light yellow acicular crystalline powder |

| Content % ≥ | 99.0 |

| Melting point | 47-49°C |

| Ash content | <0.1% |

| Transmittance 450nm500nm | >90% |

| >95% |

Properties and Usage:

UV-531 is an efficient and fast free radical (I) type light stabilizer, mainly used in UV curing coatings. Its product features include:

a) High absorption performance: In the ultraviolet spectrum range, especially in the 300-400nm band, it has a high degree of ultraviolet absorption ability, so it shows excellent light stabilization effect in plastic products.

b) Good compatibility: It has excellent compatibility with thermoplastic resins, especially polyolefins, ensuring uniform dispersion in the polymer.

c) Low volatility: It has extremely low evaporation pressure and can avoid product loss during processing.

d) Low migration: It has low migration and will not bloom.

e) Excellent heat resistance: There is no significant degradation and volatilization at extrusion temperature, showing excellent heat resistance.

f) Chemical inertness: It is chemically inert during the plastic production process and will not affect the chemical properties of the resin and dressing.

g) Odorless: It will not cause the resin to smell and complies with the hygienic standards of the product.

h) High purity: It has unique high purity and will not have a negative impact on the product due to impurity.

Application areas:

UV-531 is widely used in polymers, especially in scenes that are greatly affected by ultraviolet light. Specific applications include but are not limited to:

Polyethylene: It is very effective for both high-density and low-density polyethylene. It can be used for polyethylene flat filament, monofilament, film and other products, which can extend the service life and improve weather resistance.

Polypropylene: Effective in both colored and clear polypropylene, suitable for products such as fibers, monofilaments, plain yarns, ribbons, webs and films.

Polyvinyl chloride: In ordinary polyvinyl chloride, especially in plasticized PVC products, UV531 can effectively prevent yellowing and changes in physical properties caused by ultraviolet radiation.

SBS and PS modified TPR materials: suitable for these materials, which can improve their weather resistance and stability.

The testing methods of UV-531 include appearance testing, ultraviolet absorption spectrum testing, solubility testing, content testing, thermal stability testing, weather resistance testing and safety testing to ensure its quality and safety.

| Material | Recommended dosage | |

| Polyethylene | Monofilament, film | 0.2-0.5% |

| Blow molded products | 0.15-0.3% | |

| Agricultural plastic film | 0.5% | |

| Polypropylene | Injection molding | 0.2-0.3% |

| fiber, film | 0.5% | |

| PVC | 0.3-2% | |

| PU | 0.2-0.5% | |

| Other | Recommended dosage: 0.1-0.3%. Before use, a small test should be conducted to determine the final formula. | |

Packaging specifications:

This product is packed in 20KG or 25KG carton, lined with plastic bag, or can be customized according to customers' requirements.

Good storage stability. Store in a dry area below 25°C in a proper way.

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

IW

IW

ID

ID

LV

LV

LT

LT

SR

SR

SK

SK

VI

VI

HU

HU

TH

TH

TR

TR

GA

GA

CY

CY

KA

KA

LA

LA

MN

MN

KK

KK

LB

LB