N,N-Dimethyl-p-toluidine CAS 99-97-8

Chemical name: N,N-Dimethyl-p-toluidine

Synonymous names:

Dimethyl-p-toluidine

dimethyl-4-toluidine

N,N-Dimethyl-p-toluidine

CAS No: 99-97-8

EINECS No : 202-805-4

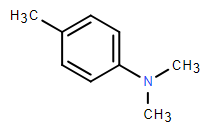

Molecular formula:C9H13N

- Parameter

- Related products

- Inquiry

Structural formula:

Product Description:

|

FSCI-Item |

Specifications |

Results |

|

Appearance |

Primrose yellow liquid |

Qualified |

|

N,N-dimethyl-p-toluidine assay |

99.00 Min |

99.36 |

|

p-toluidine assay |

0.20 Max |

0.15 |

|

N-methyl-p-toluidine assay |

0.40 Max |

0.35 |

|

Moisture ang another assay |

0.40 Max |

0.25 |

|

Conclusion |

The results conforms with enterprise standards |

|

Properties and Usage:

N,N-Dimethyl-p-toluidine (CAS No.: 99-97-8) is a widely used chemical intermediate and catalyst, widely used in resin curing, dental materials, coatings, paints, dye synthesis and other fields.

1. Curing agent for resins and polymers:

N,N-Dimethyl-p-toluidine is often used as a catalyst, especially in the curing process of epoxy resins and polyester resins. This compound can significantly improve the curing rate and the performance of the final product. Its efficient catalytic properties make it an indispensable component in the resin curing process.

2. Dental materials:

In the dental field, N,N-Dimethyl-p-toluidine is used as a curing agent for composite resins and adhesives. It helps these materials harden quickly in tooth restoration and repair work, providing the necessary strength and durability

3. Coatings and paints:

The compound is used as a curing agent in certain types of coatings and paints. It can improve the drying speed and adhesion of the coating, thereby enhancing the durability and corrosion resistance of the coating

Product advantages

1. Efficient catalysis: It can significantly improve the curing speed and quality of resins and polymers.

2. Rapid reaction: shows extremely high initiation efficiency in photopolymerization reaction

Storage and transportation:

Store in a cool, dry, ventilated place away from direct sunlight and high temperatures. At the same time, make sure that the storage container is well sealed to prevent leakage and contamination.

Packaging specifications:

Net weight: 190Kg/drum, or customized packaging according to customer requirements.

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

IW

IW

ID

ID

LV

LV

LT

LT

SR

SR

SK

SK

VI

VI

HU

HU

TH

TH

TR

TR

GA

GA

CY

CY

KA

KA

LA

LA

MN

MN

KK

KK

LB

LB