Methylhexahydrophthalic anhydride CAS 25550-51-0

Chemical name: Methylhexahydrophthalic anhydride

Synonymous names:MeHHPA;Methylhexahydrophthalic anhydrid;

Hexahydromethylphthalsureanhydrid

CAS No:25550-51-0

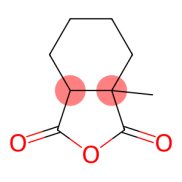

Molecular formula:C9H12O3

Molecular weight:168.19

EINECS No:247-094-1

- Parameter

- Related products

- Inquiry

Structural formula:

Product Description:

|

Items |

Specifications |

|

Appearance |

Colorless transparent liquid |

|

Assay,% |

99% min |

|

Color (Pt-Co) |

Max 5 # |

|

Iodine value |

Max 1% |

|

Free acid |

Max 0.5% |

|

Acid value (mgKOH/g) |

Min 645 |

Properties and Usage:

Methyl Hexahydrophthalic Anhydride is an important chemical raw material, mainly used in the production of epoxy resin curing agents, insulating materials, coatings and adhesives.

Applications:

1. Epoxy resin curing agent:

High-performance curing agent: Methyl Hexahydrophthalic Anhydride, as an epoxy resin curing agent, is widely used in the production of insulating materials, electronic component packaging and laminates in the electronics industry. It has good heat resistance and electrical insulation, and can enhance the mechanical properties and chemical stability of epoxy resins.

Low viscosity curing agent: Compared with other curing agents, Methyl Hexahydrophthalic Anhydride has a lower viscosity, making it easier to mix and process, and is suitable for epoxy resin systems that require good fluidity.

2. Coatings and adhesives:

Corrosion-resistant coatings: Methyl Hexahydrophthalic Anhydride can be used to prepare corrosion-resistant coatings, especially protective coatings for equipment and facilities used in marine and chemical environments.

Adhesives: It is also used to prepare high-strength structural adhesives, suitable for bonding metals, wood and plastics.

3. Other applications: Electrical insulation materials: Methyl Hexahydrophthalic Anhydride is widely used in insulation materials for cables, transformers and other electrical equipment due to its excellent electrical insulation properties. Methyl Hexahydrophthalic Anhydride is also used in the production of high-performance plastics, fibers and rubber additives.

Storage conditions: Store in a cool, ventilated, dry warehouse, fireproof, sunproof, and moisture-proof. If it comes into contact with the skin, rinse immediately with water.

Packing: This product is packed in 25kg 100kg Plastic bucket, and it can also be customized according to customers' requirements

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

IW

IW

ID

ID

LV

LV

LT

LT

SR

SR

SK

SK

VI

VI

HU

HU

TH

TH

TR

TR

GA

GA

CY

CY

KA

KA

LA

LA

MN

MN

KK

KK

LB

LB