Isopropylphenyl phosphate CAS 68937-41-7

Chemical name: Isopropylphenyl phosphate

Synonymous names:IPPP50;Phenol,isopropylated,phosphate(3:1);Phenolphosphateisopropylated

CAS No:68937-41-7

Molecular formula:C27H33O4P

Molecular weight:452.52

EINECS No:273-066-3

- Parameter

- Related products

- Inquiry

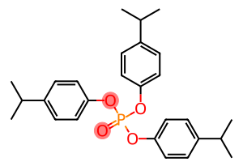

Structural formula:

Product Description:

|

Analysis terms |

Specification |

Analysis results |

|

Appearance,visual |

Clear transparent liguid |

Clear transparent liguid |

|

Hazen color value |

≤50 |

42 |

|

Wate content,% |

≤0.1 |

0.037 |

|

Refractive index |

1.546-1.555 |

1.549 |

|

Acid value |

≤0.1 |

0.043 |

|

Loss on heating |

≤0.15 |

0.033 |

|

粘度 Viscosity |

48-64 |

50 |

|

Density g/ml,20℃ S.G |

--- |

1.17 |

|

Conclusion |

Qualified |

|

Properties and Usage:

Isopropylated Triphenyl Phosphate is a phosphate compound with flame retardancy, low volatility and excellent heat resistance, and plays an important role in industrial applications. As a highly efficient additive, IPTPP is mainly used in plastics, rubber, coatings, lubricants and other fields.

Main application areas:

1. Flame retardant:

Plastics and rubber: Isopropylphenyl phosphate is widely used in plastic and rubber products such as PVC, polyurethane, and epoxy resin, significantly improving the flame retardant properties of the material.

Wires and cables: In the production process of wires and cables, IPTPP acts as a flame retardant to ensure the stability and safety of the material under high temperatures and electrical faults.

2.Plasticizer:

PVC products: As a plasticizer, Isopropylphenyl phosphate can improve the flexibility and processing properties of PVC and is widely used in the manufacture of cable sheaths, films, pipes and flooring materials.

Rubber products: In the rubber industry, IPTPP not only improves the processing performance of rubber, but also enhances its wear resistance and weather resistance.

3. Lubricant additives:

Industrial lubricants: can be used as an additive to lubricants, especially under high temperature and high pressure conditions, to enhance the oxidation resistance and wear resistance of lubricants and extend the service life of equipment.

4. Coatings and adhesives:

Coatings: In coating formulations, can improve the chemical resistance and durability of coatings while enhancing corrosion resistance.

Adhesive: In the adhesive formula, the flexibility and adhesion of the adhesive are improved

Storage conditions: Avoid contact with fire and store in a cool, dry place.

Packing: This product is packed in 25kg 100kg 200kg drums, and it can also be customized according to customers' requirements

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

IW

IW

ID

ID

LV

LV

LT

LT

SR

SR

SK

SK

VI

VI

HU

HU

TH

TH

TR

TR

GA

GA

CY

CY

KA

KA

LA

LA

MN

MN

KK

KK

LB

LB