UV-531 CAS 1843-05-6

Kémiai név: Octabenzone

Szinkron név(ek): CHIMASSORB 81;

BENZOPHENONE-12;

UV Abszorber 531

BP-12

2-Hidroksi-4-n-oktyloksibenzofenon

CAS szám: 1843-05-6

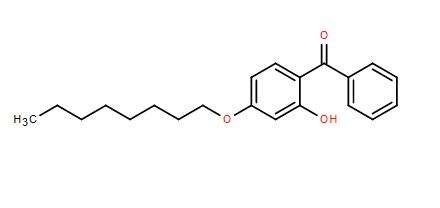

Molekuláris képlet: C21H26O3

Tartalom: ≥99%

Részecsketömeg: 326.432

EINECS: 217-421-2

- Paraméter

- Kapcsolódó termékek

- Vizsgálat

Szerkezeti képlet:

A termék leírása:

| Index | Specifikációk |

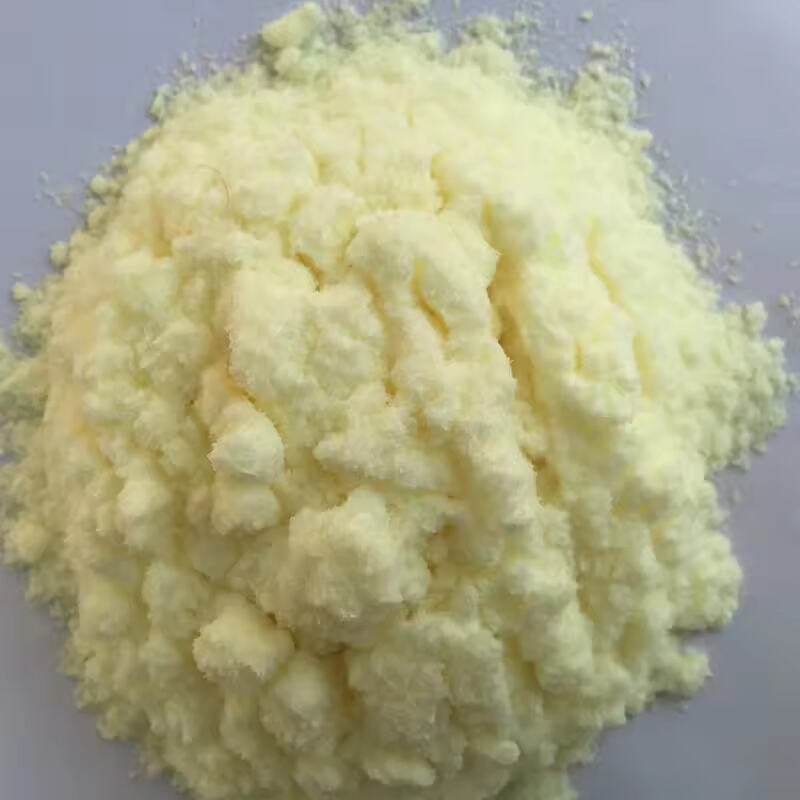

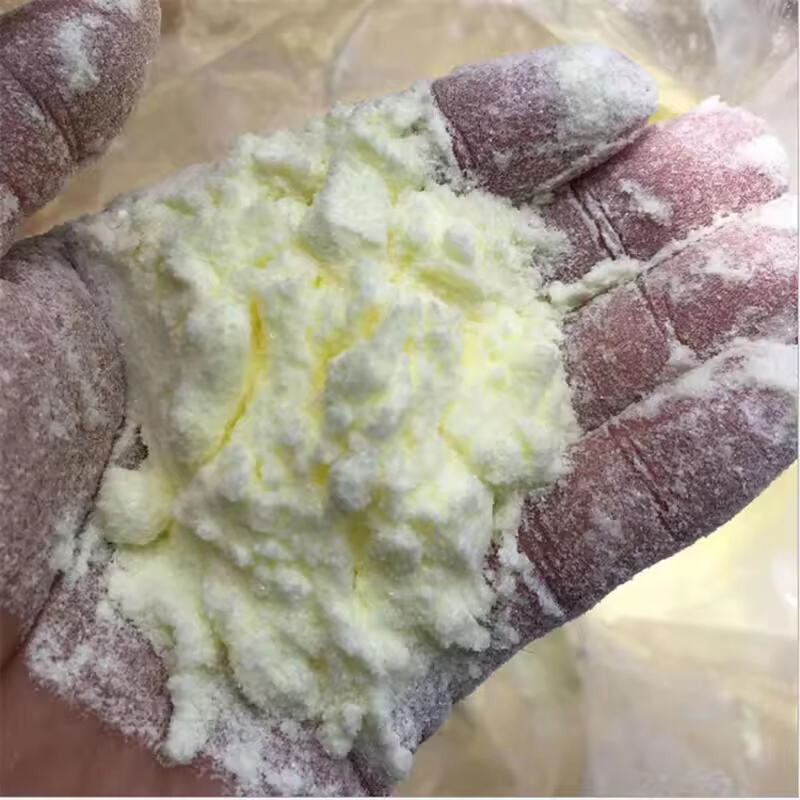

| Megjelenés | Világos sárga szigetgumi krystallinis por |

| Tartalom % ≥ | 99.0 |

| Olvadáspont | 47-49°C |

| Hamutartalom | < 0,1% |

| Átjárhatóság 450nm500nm | >90% |

| >95% |

Tulajdonságok és Használat:

A UV-531 egy hatékony és gyors szabad radikális (I) típusú fénystabilizátor, főként UV-megcélzott festékekben használják. A termék jellemzői közé tartoznak:

a) Magas felszívó teljesítmény: Az ultraviolett spektrumtartományban, különösen a 300-400nm sávszélességben nagyfokú ultraviolett felszívó képességgel rendelkezik, így kitűnő fénystabilizáló hatást mutat plasztik termékek esetén.

b) Jó kompatibilitás: Kitűnő kompatibilitást mutat a hőmérsékleti polimeres anyagokkal, különösen a polioléfinekkel, amely biztosítja a polymerek egyenletes eloszlását.

c) Alacsony volatilitás: Rendkívül alacsony feszültséggel rendelkezik, és elkerüli a termék veszteségét a feldolgozás során.

d) Alacsony migráció: Alacsony migrációt mutat, és nem tér fel.

e) Kitűnő hőállóság: A nyomás köztemperatúrájánál nincs jelentős degradáció és volatilitás, ami kitűnő hőállóságot mutat.

f) Kémiai inerciáság: Kémiai inerciás a plasztik gyártási folyamatában, és nem befolyásolja a rezinák és az illesztőanyagok kémiai tulajdonságait.

g) Gyógyszertelen: Nem okoz részelést a rezinának, és megfelel a termék egészségügyi szabványainak.

h) Magas szűzseg: Egyedülálló magas szűzsegé van, és nem lesz negatív hatása a termékre az impureitás miatt.

Alkalmazási területek:

A UV-531 széleskörben használják a polimeres anyagokban, különösen azokban a helyzetekben, amelyek nagyon érzékenyek az ultraviolett sugárzásra. A konkrét alkalmazások közé tartozik, de nem korlátozódnak erre:

Polie tilen: Mind a magas-sűrűségű, mind a alacsony-sűrűségű polie tilenre nagyon hatékony. Használható polie tilen síkfolt, egyfoltos szál, filmtípusok és más termékek esetén, amelyek hosszabb szolgáltatóidőt biztosítanak és növelik az időjárás elleni ereklyét.

Polipropilen: Mind a színes, mind a világos polipropilene hatékony, alkalmas szál, egyfoltos szál, egyszínű szál, csíkozott szál, rács és film termékekre.

Polivinilclorid: Az általános polivinilclorida, különösen a plastifikált PVC termékekben, a UV531 hatékonyan megakadályozza az ultraviolett sugárzás által okozott sárgásodást és fizikai tulajdonságok változását.

SBS és PS módosított TPR anyagok: alkalmas ezekre az anyagokra, amelyek javíthatják az időjárás elleni ereklyét és stabilitást.

A UV-531 tesztelési módszerei közé tartozik a kinézet tesztelése, az ultraviolett abszorpcióspektrum tesztelése, a oldhatóság tesztelése, a tartalom tesztelése, a hőmérsékleti stabilitás tesztelése, az időjárás elleni ellenálló tesztelés és a biztonsági tesztelés annak érdekében, hogy megőrizzük minőségét és biztonságát.

| Anyag | Ajánlott adagolás | |

| Poliethylen | Egyfilament, színfilm | 0.2-0.5% |

| Fúvás termékek | 0.15-0.3% | |

| Kertészeti plastikfilm | 0,5% | |

| Polipropilen | injekciós formázás | 0.2-0.3% |

| szál, film | 0,5% | |

| PVC | 0.3-2% | |

| PU | 0.2-0.5% | |

| Más | Ajánlott mennyiség: 0.1-0.3%. A használat előtt kis kísérletet kell végrehajtani a végső képlet meghatározásához. | |

Csomagolási norma:

A termék 20KG vagy 25KG kartonban van csomagolva, plasztikos zacskóval felpárnázva, vagy testreszabható a vásárlók igényei szerint.

Jó tárolási stabilitás. Tárolja egy 25°C-nál alacsonyabb, száraz helyen megfelelő módon.

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

IW

IW

ID

ID

LV

LV

LT

LT

SR

SR

SK

SK

VI

VI

HU

HU

TH

TH

TR

TR

GA

GA

CY

CY

KA

KA

LA

LA

MN

MN

KK

KK

LB

LB