Bismaleimid (BMI) CAS 13676-54-5

Kemijsko ime : Bismaleimid

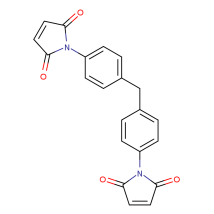

Sinonimni nazivi :BMI; BISMALEIMID; 4,4'-METILEN-BIS(N-FENILMALEIMID)

CAS br. :13676-54-5

Molekularna formula :C21H14N2O4

Molekularna težina :358.35

EINECS Ne :237-163-4

- Parametar

- Srodni proizvodi

- Upit

Strukturalni obrazac :

Opis proizvoda :

|

Analiza Sljedeći članak |

Standard |

Rezultati |

|

Izgled |

Svjetložuti ili žuti kristalni prašek |

Svjetložuta kristalna prašina |

|

Čistoća |

≥ 99.0% |

99.2% |

|

Talište |

150℃ -160℃ |

152℃ -158℃ |

|

Kiselina vrijednost ,mG KOH /g |

≤ 0.10% |

0.51% |

|

Voda |

≤ 0.10% |

0.16% |

|

Vrijeme zaređivanja s na 200 ° C ( 1 g uzorak ) |

< 300 |

74 |

|

Zaključak |

Odgovara |

|

Svojstva i Upotreba :

N,N'-(4,4'-metilendifenil) bismaleimid (BMI) je visoko performantna organska spojina široko korištena u materijalnoj znanosti i inženjerstvu. Kao činioca otežavanja epoksidnih lemjiva i materijala termoset lemjiva, BMI igra važnu ulogu u mnogim industrijskim granama s njegovom jedinstvenom molekularnom strukturom i odličnim fizičkim svojstvima.

Glavna područja primjene

1. Visoko performantne složene materijale

Aerosvemski: Rezina bismaleimid se koristi u nosivim dijelovima zrakoplova, strela i satelita. Zahvaljujući svojoj otpornosti na visoke temperature i koroziju, ostaje stabilna u ekstremnim uvjetima.

Automobil: Kao laki materijal, rezina BMI poboljšava troškove goriva i smanjuje emisije.

2. Elektronika i elektrotehnika

Štampane krugove: Rezina bismaleimid iznosi odličnu električnu izolaciju i otpornost na toplinu, te je prilagođena visokofrekventnim i visokobrzinskim krugovima.

Materijali za električnu izolaciju: Zahvaljujući svojim izuzetnim dielektričnim svojstvima, široko se koristi u proizvodnji izolacijskih materijala u visokotemperaturnim i visokofrekventnim uvjetima.

3. Lijepila i obloge

Strukturna lijepila: Rezina BMI ima visoku čvrstoću i trajnost, te je prilagođena upotrebi u visokotemperaturnim uvjetima, posebno u elektronskom pakiranju i proizvodnji složenih materijala.

Oblačiva za visoke temperature: BMI-bazirane smole koriste se u industrijskim oblačivama i široko se primjenjuju u područjima nafte i plina, zrakoplovnosti i energije.

4. Termodurabilne smole

Materijali za formiranje: BMI smole su kopolimerizirane ili prepletena s drugim materijalima kako bi se stvorile termodurabilne smole s viskom čvrstošću, niskom suženjem i odličnom otpornost još na kemijske tvari.

Zatvrditelj: Koristi se za modifikaciju drugih termodurabilnih smola kako bi se poboljšala njihova otopst i otpornost na udar.

5. Pojačavač složenih materijala

BMI smole često se koriste kao pojačavači u vlaknovitim plastmassama što značajno poboljšava mehanička svojstva i otpornost na toplinu, a posebno su prilagođene visokotemperaturnim i visokonapornim okruženjima.

Uvjeti skladištenja: Držati zatvoreno. Čuvati u hladnom, suhom i ventiliranom prostoru.

Pakiranje: Ovaj proizvod je ambala u vreće od 25kg, 100kg, 200kg, a također se može prilagoditi prema zahtjevima kupaca.

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

IW

IW

ID

ID

LV

LV

LT

LT

SR

SR

SK

SK

VI

VI

HU

HU

TH

TH

TR

TR

GA

GA

CY

CY

KA

KA

LA

LA

MN

MN

KK

KK

LB

LB