GMA CAS 106-91-2

Chemical name:Glycidyl methacrylate

Synonymous names:Epoxypropyl methacrylate;2,3-Epoxypropyl methacrylate;GMA

CAS No:106-91-2

Molecular formula:C7H10O3

Content:≥99%

Molecular weight:142.154

- Parameter

- Related products

- Inquiry

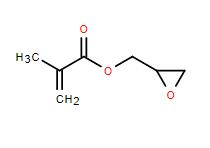

Structural formula:

Product Description:

| ANALYSISITEMS | SPECIFICATIONS |

| APPEARANCE | COLORLESS LIQUID |

| PURITY(%) | ≥99.2 |

| MOISTURE% | ≤0.1 |

| CHROMA( PT-CO) | ≤25 |

| MEHQ ppm | 50-150 |

| (EEW)g/mol | 140-150 |

| Density | 1.072 g/mL at 25 °C |

| Viscosity | low viscosity |

| Skin irritation | Moderate |

| Reactivity | Very high |

| High temperature resistance | relatively high |

Properties and Usage:

Glycidyl Methacrylate (GMA) is a multifunctional monomer with acrylate double bonds and epoxy groups. It is widely used in various fields because of its unique structure and multifunctional properties. Applications.

Main features:

Versatility: With acrylate double bonds and epoxy groups, it can undergo self-polymerization, copolymerization, and reactions with other functional groups to introduce more functionality, such as toughening, cross-linking, etc.

Excellent physical properties: It is usually a colorless, transparent and low-viscosity liquid with good fluidity and coating properties. It is soluble in common organic solvents but insoluble in water.

High reactivity: It has extremely high reactivity and plays an important role in the synthesis and modification process, which is beneficial to accelerating the reaction rate and increasing the yield of the product.

Good chemical resistance: It has excellent chemical resistance and strong stability against chemicals in the environment, which can protect the substrate and extend the service life of the product.

Wide range of applications: It has important applications in powder coatings, thermosetting coatings, fiber treatment agents, adhesives, antistatic agents, stabilizers and other fields, providing products with excellent performance and functionality.

The main purpose:

Powder coating: Used to prepare powder coating matt resin for outdoor use. It has excellent leveling performance, weather resistance and chemical resistance, and can be used for coating metal, plastic and other substrates.

Plastic modification: GMA can be grafted onto polymers and used as a toughening agent to improve the toughness of engineering plastics or a compatibilizer to improve the compatibility of blending systems, while also improving the chemical resistance and wear resistance of plastic products.

UV glue: As a UV free radical monomer, GMA plays a role in free radical cationic curing, has good bonding effect and high-strength curing effect, and is suitable for optical devices, electronic products and other fields.

PCB ink: It can be used to produce circuit board ink. It provides acrylic system green oil with excellent adhesion, abrasion resistance and chemical resistance, and is suitable for the preparation of PCB printed circuit boards.

Polymer synthesis: As an important fine chemical raw material, it can be used in acrylic resin/emulsion synthesis, polyvinyl chloride coatings, hydrogenated LER substitutes and other fields to provide support for the synthesis of polymer materials.

Production Process:

The production of glycidyl methacrylate usually follows a two-step process. First, methacrylic acid and epichlorohydrin are subjected to a ring-opening esterification reaction to generate 2-hydroxy-3-chloropropyl methacrylate. Then, in the presence of hydroxyl radicals, a ring-closing reaction of dehydrochlorination is performed to obtain the target product.

Application areas:

Glycidyl methacrylate is widely used in acrylic coatings, acrylic ester coatings, alkyd resin coatings, vinyl chloride resins, powder coatings, and UV glue.

Packaging specifications:

This product uses 200kg plastic drums or galvanized drums. Or customized according to customer's requirements

Store in a cool, ventilated place in a closed and dark place. Keep away from fire. It should be stored separately from acids and oxidants and should not be mixed.

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

IW

IW

ID

ID

LV

LV

LT

LT

SR

SR

SK

SK

VI

VI

HU

HU

TH

TH

TR

TR

GA

GA

CY

CY

KA

KA

LA

LA

MN

MN

KK

KK

LB

LB