Dibutyl phthalate CAS 84-74-2

Chemical name: Dibutyl phthalate

Synonymous names:

DBP

ARALDITE RESIN

Butyl phthalate

CAS No: 84-74-2

EINECS: 201-557-4

Molecular formula: C16H22O4

Content: ≥99%

Molecular weight: 278.34

- Parameter

- Related products

- Inquiry

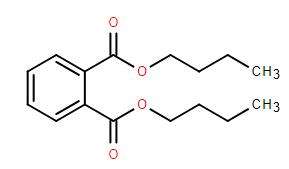

Structural formula:

Product Description:

| Item | Specification(Premium) | Specification (Qualified) |

| Chroma (platinum-cobalt), number | 20 Max | 25 |

| Acid value, mgKOH/g | 0.07 Max | 0.11 |

| Density (20℃), g/cm3 | 1.046±0.002 | 1.046±0.002 |

| Content (GC), % | 99.5 Min | 99.0 |

| Flash point, ℃ | 160 Min | 160 |

| Moisture, % | 0.10 Max | 0.15 |

| FSCICHEM produces three grades of DBP. If you need customization, please contact info@fscichem.com | ||

Properties and Usage:

Dibutyl phthalate (DBP) is a commonly used plasticizer, mainly used for plasticizing cellulose resin and polyvinyl chloride. It has excellent solubility and decomposition properties, and the softness and stability of the paint film are also very good. DBP is widely used in plastics, rubber, paint and other industries, and can be used as lubricants, emulsifiers, gas chromatography fixatives and high-boiling point solvents.

At the same time, the use in nitrocellulose paint has a good softening effect on the paint and can provide good softness and stability.

This plasticizer is fully compatible with vinyl resin, cellulose and other resins, so it is often used as the main plasticizer for cellulose resin and polyvinyl chloride. Although its durability and pull-out resistance are relatively poor, it is excellent in plasticizing effect. In addition, DBP is also used as a plasticizer for polyvinyl acetate, alkyd resin, ethyl cellulose, and chloroprene rubber. It plays an important role in the processing of materials such as nitrocellulose, acetate and polyvinyl chloride.

Advantage:

1. Good processability: Although the volatility and water extractability of DBP are relatively large, which makes the durability of the products slightly insufficient, DBP as a plasticizer can effectively improve the softness and processability of plastics and rubber, making the products easier to process. forming. And low cost.

2. Wide range of applications: It has good application effects in cellulose resin, polyvinyl chloride and other resins, and is also used in many industries such as coatings, artificial leather, and printing inks.

3. Strong compatibility: It has good compatibility with most resins such as vinyl resin and cellulose, and has significant plasticizing effect.

shortcoming:

1. Poor durability: The durability and resistance to extraction of DBP are relatively poor, which may cause the performance of the product to decline after long-term use.

2. High volatility: Under certain conditions, DBP may have a certain volatility, so attention needs to be paid to its potential impact on the environment and human body.

Recommended use: Mixed with other Fscichem plasticizer products.

Storage and transportation:

The product should be kept away from light and should be protected from impact, fire, sun and rain during transportation. The product should be stored in a dry, ventilated warehouse, away from heat and fire.

Packaging specifications:

Net weight 200kg/drum,or customized packaging according to customer requirements.

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

IW

IW

ID

ID

LV

LV

LT

LT

SR

SR

SK

SK

VI

VI

HU

HU

TH

TH

TR

TR

GA

GA

CY

CY

KA

KA

LA

LA

MN

MN

KK

KK

LB

LB