Diacetone acrylamide CAS 2873-97-4

Chemical name: Diacetone acrylamide

Synonymous names:DAAM;Diacetonyl acrylamide;DIACETONE ACRYLAMIDE

CAS No:2873-97-4

Molecular formula:C9H15NO2

Molecular weight:169.22

EINECS No:220-713-2

- Parameter

- Related products

- Inquiry

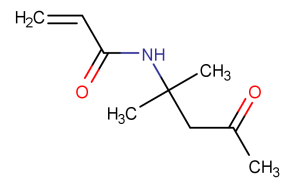

Structural formula:

Product Description:

|

ITEMS |

SPECIFICATIONS |

RESULTS |

|

Appearance |

White to slightly yellow flakes |

White flakes |

|

Melting point (℃) |

55.0-57.0 |

55.8 |

|

Purity (%) |

Minimum 99.0 |

99.37 |

|

Water (%) |

Maximum 0.5 |

0.3 |

|

Inhibitor (PPM) |

Maximum 100 |

20 |

|

Acrylamide (%) |

Maximum 0.1 |

0.07 |

|

Solubility in water (25℃) |

Minimum 100g/100g |

Complies with |

Properties and Usage:

Diacetone acrylamide (CAS 2873-97-4) is an important cross-linker used in plastics, resins, adhesives, coatings, textiles, rubber and composite manufacturing.

1. Plastic and resin processing: Diacetone acrylamide can copolymerize with monomers in the cross-linking of epoxy resin and unsaturated polyester resin, greatly improving the mechanical strength, heat resistance, chemical corrosion resistance and dimensional stability of the resin. sex.

2. Enhance adhesive performance: As a cross-linking agent, diacetone acrylamide can effectively improve the adhesion and durability of adhesives.

3. Wear-resistant and anti-corrosion coating: Diacetone acrylamide in the coating formula can significantly improve the wear resistance and corrosion resistance of the coating. It is especially suitable for surface protective coatings that need to be exposed to harsh environments for a long time. Such as industrial equipment and ship painting, ensuring the stability and long-term effectiveness of the coating.

4. Improve textile properties: Diacetone acrylamide is used as an auxiliary in textile processing to improve the wear resistance and service life of fabrics. It helps textiles maintain good appearance and structure by improving their stability and resistance to washing, especially for products that are washed frequently.

5. Improve the physical properties of rubber: In rubber production, diacetone acrylamide is used to enhance the hardness, elasticity and wear resistance of rubber, making it more durable and suitable for various complex applications, including automotive parts and industrial equipment seals of manufacturing.

6. Enhance the strength and durability of composite materials: Diacetone acrylamide can improve the strength and service life of composite materials in the aerospace, automotive and construction fields.

Storage conditions: Keep container tightly closed in a dry, ventilated place. Opened containers must be carefully resealed and kept upright to prevent leakage.

Packing: This product is packed in 20kg 50kg Carton, and it can also be customized according to customers' requirements

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

IW

IW

ID

ID

LV

LV

LT

LT

SR

SR

SK

SK

VI

VI

HU

HU

TH

TH

TR

TR

GA

GA

CY

CY

KA

KA

LA

LA

MN

MN

KK

KK

LB

LB