Bisphenol-A bis(diphenyl phosphate) CAS 5945-33-5 Flame retardant BDP

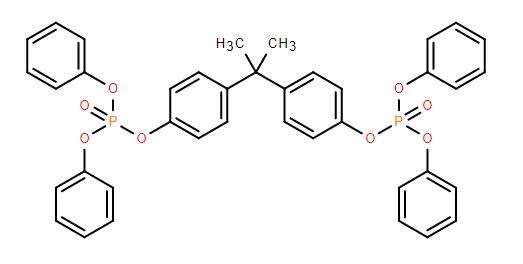

Chemical name: Bisphenol-A bis(diphenyl phosphate)

Synonymous names: Reofos BAPP

Fyrolflex BDP

2,2-Bis[4-[bis(phenoxy)phos

CAS No:5945-33-5

Molecular formula: C39H34O8P2

Appearance: Colorless to light yellow transparent liquid

Molecular weight: 692.64

EINECS: 425-220-8

- Parameter

- Related products

- Inquiry

Structural formula:

Product Description:

| Index | Specifications |

| Appearance | Colorless to light yellow transparent liquid |

| APHA | Not more than 80 |

| Acid value,(mgKOH/g) | 0.1MAX |

| Moisture,% | 0.1MAX |

| N=1 Content, (wt. %) | 80-89 |

| Phosphorus Content (wt. %) | 8.9 |

| TPP Content (wt. %) | 3.0MAX |

| IPP Content (wt. %) | 0.05MAX |

| Phenol Content(wt. %) | 0.05MAX |

| Density(25°C, g/cm3) | 1.250-1.270 |

| Viscosity(40°C, mPa`s) | 1800-2600 |

Flame retardant BDP is a halogen-free phosphate flame retardant, which provides an efficient and environmentally friendly solution for industrial production. As an advanced flame retardant plasticizer, BDP combines the advantages of traditional monophosphate flame retardants and improves several key properties.

Properties and Usage:

1.High compatibility: Bisphenol-A bis(diphenyl phosphate) has excellent compatibility with a variety of polymers such as PC/ABS (polycarbonate/acrylonitrile butadiene styrene) and engineering plastics such as PPO/HIPS (polyphenylene ether/high impact polystyrene). capacitive and does not affect the original properties of the polymer.

2.Low volatility and excellent hydrolytic stability: Bisphenol-A bis(diphenyl phosphate) has extremely low volatility, which can maintain the stability of the material during processing and use and reduce quality loss caused by volatilization. At the same time, its excellent hydrolytic stability means it is not prone to decomposition even in humid environments, ensuring long-term durability of the product.

3.Excellent thermal stability: Bisphenol-A bis(diphenyl phosphate) can remain stable in high temperature environments and enhance the high temperature resistance of the polymer.

Application areas

1.Due to its excellent flame retardant effect and thermal stability, BDP is widely used in multiple industries, including:

2.Plastic and rubber products: Improve the flame retardant properties of these materials to ensure that the burning rate of the materials is reduced in a fire accident and improve overall safety.

3.Coatings and Textiles: By applying to coatings and textile materials, BDP increases the protection capabilities of these products when exposed to high temperatures or sources of fire.

4.High thermal stability application: Especially suitable for products that require high temperature resistance. The thermal stability of PVC can also be greatly improved by adding BDP.

Packing: This product is packed in 250KG iron drum or IBC drum with a net weight of 1250kg or ISOTANK with a net weight of 20-25 tons

Storage conditions: This product should be stored in a dry and cool environment, avoid high temperature during storage and transportation, and pay attention to waterproof and moisture-proof. When handling this product, avoid strong rubbing to prevent damage to the package.

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

IW

IW

ID

ID

LV

LV

LT

LT

SR

SR

SK

SK

VI

VI

HU

HU

TH

TH

TR

TR

GA

GA

CY

CY

KA

KA

LA

LA

MN

MN

KK

KK

LB

LB