Antioxidant 264 CAS 128-37-0

Chemical name: Butylated Hydroxytoluene

Synonymous names: Antioxidant 264

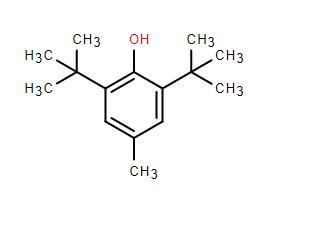

2,6-Di-tert-butyl-4-methylphenol

Anitioxidant BHT

CAS No: 128-37-0

Molecular formula: C15H24O

Molecular weight: 220.35

EINECS No: 204-881-4

- Parameter

- Related products

- Inquiry

Structural formula:

Product Description:

| Index | Specifications |

| Appearance | White crystal |

| Melting point | 69-73 °C |

| Moisture,% | 0.05MAX |

| Ash,% | 0.01MAX |

| Free Phenol (p-cresol),% | 0.015MAX |

Antioxidant 264, as a traditional hindered phenolic antioxidant, not only provides efficient protection, but also has a wide range of applications, whether it is industrial oils or food-grade plastics.

Properties and Usage:

1.Efficient antioxidant capacity: Antioxidant 264 prevents material oxidation, extends the service life of the product and maintains stable performance. It has a strong protective effect on polymers, rubber and oils.

2.Compatibility: This antioxidant is well compatible with a variety of resins and oils, including polypropylene, polyethylene, ABS resin, polystyrene, and polyester, making it effective in a variety of materials.

3.Environmental protection and safety: Antioxidant 264 complies with FDA requirements, is non-toxic and non-polluting, and is suitable for food-grade materials and packaging to ensure food safety.

4.Flexibility of use: Due to its liquid form, Antioxidant 264 is easy to dose and add, whether during production or as a maintenance additive.

Application areas

1.Industrial oils and lubricants: In the petroleum industry, antioxidant 264 is used in various lubricants, gasoline, paraffin and other mineral oils to improve their stability and extend their service life.

2.Plastic and rubber manufacturing: It is widely used in the manufacture of various plastic and rubber products, especially in polyether and polyurethane, natural and synthetic rubber, to effectively prevent material aging.

3.Food packaging: As a food additive, antioxidant 264 delays food rancidity and is especially suitable for food-grade plastics and food packaging materials to ensure food quality and safety.

4.Fuel additives: Adding antioxidant 264 to fuel can improve the stability of gasoline and diesel.

Recommended dosage

1.The usage amount of polymers such as polyethylene and polypropylene is usually between 0.01% and 1%.

2.The dosage in rubber and elastomer products is generally 0.5% to 3%.

3.The recommended dosage of lubricants and mineral oils is 0.1% to 1%.

4.Approximately 0.3% in gasoline and diesel.

Packing: This product is packed in cardboard drums, lined with plastic bags and 3-in-1 paper bags, net weight 25kg. It can also be customized according to customer requirements

Storage conditions: This product should be stored in a dry and cool environment, avoid high temperature during storage and transportation, and pay attention to waterproof and moisture-proof. When handling this product, avoid strong rubbing to prevent damage to the package.

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

IW

IW

ID

ID

LV

LV

LT

LT

SR

SR

SK

SK

VI

VI

HU

HU

TH

TH

TR

TR

GA

GA

CY

CY

KA

KA

LA

LA

MN

MN

KK

KK

LB

LB