Antioxidant 1098 CAS 23128-74-7

Chemical name: Antioxidant 1098

Synonymous names: IRGANOX 1098

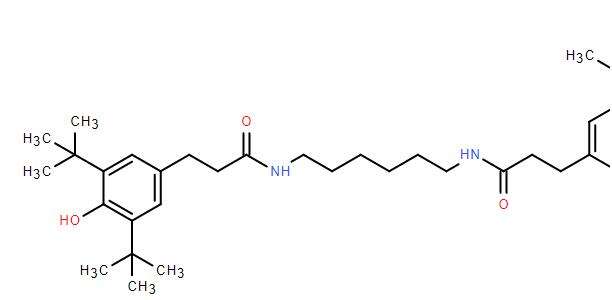

1,6-Bis-(3,5-di-tert-butyl-4-hydroxyhydrocinnamido)-hexane

3,3'-Bis(3,5-di-tert-butyl-4-hydroxyphenyl)-N,N'-hexamethylenedipropiomide

CAS No: 23128-74-7

Molecular formula: C40H64N2O4

Purity: 98%

Molecular weight: 636.95

EINECS No:245-442-7

- Parameter

- Related products

- Inquiry

Structural formula:

Product Description:

| Index | Specifications |

| Appearance | White or white crystalline solid powder |

| Melting point | 156-161°C |

| Loss on heating % | 0.30MAX |

| Ash,% | 0.10MAX |

| Volatility % | 0.5MAX |

| Solubleness | Limpidity |

| Transmittance 425nm500nm | 97MIN98MIN |

| Purity (HPLC),% | 98.0MIN |

Antioxidant 1098 is a highly efficient hindered phenolic primary antioxidant, which is widely used in the stabilization process of various polymer materials. Its main function is to provide excellent thermal processing protection and long-term resistance to aging and degradation. As a general antioxidant, it is especially suitable for stabilizing the production process of polyamide injection molding, fibers and films. The molding material has better stability and longer stability time.

Properties and Usage:

Features:

1. Excellent heat resistance and extraction resistance,

2. Good non-staining property in the initial stage,

3. Colorless pollution, low volatility

4. And excellent compatibility with most polymer materials.

5. The material with strong extraction resistance has excellent aging resistance and decomposition resistance.

Scope of application:

1. Polyamide: Used as a stabilizer to stabilize polyamide injection molding.

2. Organic basic materials such as polystyrene, polyolefin, ABS resin, acetal resin, polyurethane: provide stabilization treatment for these materials. Effectively prevents discoloration caused by high temperatures.

3. Fiber material: added to synthetic fibers to give the material good oxidation resistance.

Recommended usage: Use in the same way as thioester antioxidants produced by Fscichem, such as DLTDP and DSTDP.

Dosage: 0.05-0.5% is optimal, and can be used according to the specific formula.

Storage conditions: In a dry and cool environment, avoid high temperature during storage and transportation, and pay attention to waterproof and moisture-proof.

Packing: This product uses two kinds of carton lined with plastic bags and paper bags, with a net weight of 25 kg 500kg. It can also be made according to customer requirements

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

IW

IW

ID

ID

LV

LV

LT

LT

SR

SR

SK

SK

VI

VI

HU

HU

TH

TH

TR

TR

GA

GA

CY

CY

KA

KA

LA

LA

MN

MN

KK

KK

LB

LB