HS-508 (292) CAS 41556-26-7

Kjemisk navn: Bis(1,2,2,6,6-pentametyl-4-piperidyl) sebacat

Synonyme navn: UV-3765;

UV-292;

Lysstabilisator 292

CAS NR: 41556-26-7

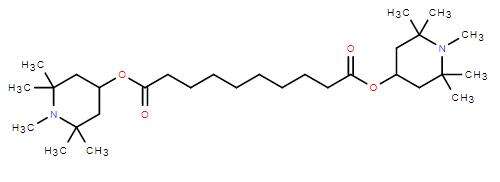

Molekylformel: C30H56N2O4

Molekylvekt: 508.78

Innhald: ≥96.0%

EINECS: 255-437-1

- Parameter

- Relaterte produkter

- Spørre

Strukturell formel:

Produktbeskrivelse:

| Indeks | Spesifikasjoner |

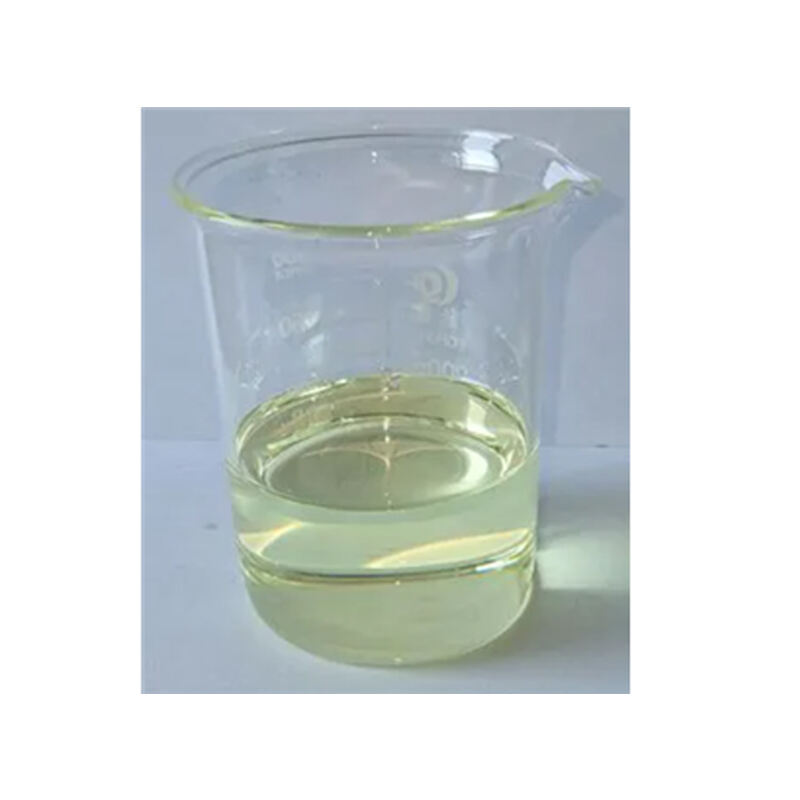

| Utseende | Lys gult væsket |

| Innhold | 96.0MIN |

| Monoester | 15.00-25.00% |

| Diester | 75.00-85.00% |

| Flyktig Materie | 0.50maks |

| Askeinnhold | 0.10maks |

| Grunnleggende egenskaper | Tetthet 0.9925 |

| Fryspunkt 20°C | |

| Kokpunkt 220°C (26,7 Pa) | |

| Variasjon | Lav damptrykk |

| Transmittanse 450nm 500nm | ≥98,00% |

| ≥99,00% |

Egenskaper og bruk:

HS-508(292) er en flerbruksvisk alkalisk hindret aminlysstabilisator, hovedsakelig brukt i maler, overflater, trykke, polyuretanmaler og andre områder. Den kan effektivt forhindre at overflaten mistet glans, sprakk, bløfnet, løftet seg og farget endret seg ved utssetting for sollys, dermed øke tjenestelivet til overflaten og produktene som brukes. Fsci lysstabilisator UV-292 har samme ytelse som Tinuvin292, og effekten kan maksimeres når den brukes sammen med ultraviolettabsorbereren produsert av Fscichem. For teknisk støtte, vennligst kontakt vårt selskaps tekniske personell.

Produktegenskaper:

1. Gir materialet langtidsvarme-stabilitet

2. Har god kompatibilitet med flere typer overflater.

3. Med fremragende varighet og høy ytelse, egnet for solventbaserte og ytre overflateanvendelser.

4. Kan brukes sammen med UV-absorberere for å forbedre klimatilpasning.

5. Forhindre effektivt kløstningproblemer forårsaket av sollys, som for eksempel sprakkning, tap av blankhet, pukking, løfting og fargeendring osv. Derfor kan det beste spille sin rolle når det brukes i bilfarger.

6.Ideal plast masterbatch tilsetninger

Hovedformålet:

1. Brukes som lysstabilisator, bredt brukt i farger, inker, polyuretanfarger og andre områder.

2. Forbedre ytelsen på fargen under sollys-eksponering, sikre blankhet, og unngå sprakkning, flekker, utbrudd og overflate-løfting, dermed forlenge livstiden til fargen.

Søknadsomfang:

1.Industrielle farger

2.Autofarger

3. Rullfarging

4. Tre-farge

5. Strålingshardende farger

6.Ink

Forpakningspecificasjoner:

Bruk av 25 kg, 180 kg galvanisert trommel eller plasttrommel-pakking tilpasses også etter kundekrav.

Lagre i et kult, tørrt og ventilert sted, unna direkte sollys. I et tørrt område under 25°C, er holdbarheten to år.

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

IW

IW

ID

ID

LV

LV

LT

LT

SR

SR

SK

SK

VI

VI

HU

HU

TH

TH

TR

TR

GA

GA

CY

CY

KA

KA

LA

LA

MN

MN

KK

KK

LB

LB