Kreozotas: daugiafunkcijinių chemikalų pramoninis ir aplinkos taikymas

Kreozotas: daugiafunkcijinių chemikalų pramoninis ir aplinkos taikymas Chemikalijos Kreozotas , kaip svarbi cheminė medžiaga, plačiai naudojamas daugelyje pramoninių sričių, ypač gumos pramonėje, dakno gamyboje, vandens apdorojime , medžio konservavime ir Cheminis sintezė . Jis netiksliai turi puikius fizinius ir cheminius savybes, bet taip pat užima vietą šiuolaikinėje che minėje rinkoje dėl savo aplinkosaugos savybių. Ši straipsnis išsamiai analizuos kreozoto įvairius taikymus ir ištirs jo inovatyvų naudojimą skirtingose srityse.

Kas yra kreozotas?

Kreozotas (CAS 8001-58-9) , taip pat žinomas kaip fenolinis smolių aliejus, yra tamsus cheminė medžiaga, gaunama iš angliavos smolės, medžio ar kitų organinių suvaromųjų medžiagų per pirkinimą ar destilavimą, pagrindinėmis sudedamosiomis dalimis yra fenolinių junginių. Jis turi stiprią aromatinę kvapą ir aukštą cheminių reakcijų gebėjimą, bei yra svarbi suvaromoji medžiaga daugelyje pramoninėse gamybose.

Pagrindiniai krekosoto taikymo sritys e

1. Krekosoto taikymas medžio saugojime :

Kreozotas plačiai naudojamas medžio saugojimo srityje. Jo fenolinės jungtinės turi stiprius antibakterinius ir antifunginius savybes, kurie efektyviai gali užkirsti kelią medžio infekcijoms dėl mikroorganizmų ir sumažinti pargaužimo riziką. Kreozoto penetravimas į medžio ląstelės struktūrą ne tik padidina jo korozijos varžymo gebėjimus, bet ir pagerina medžio antioxidantinę gebėjimą bei išilgina jo tarnybos laiką. Dėl savo natūralumo ir mažo toksiškumo kreozotas taps idealia alternatyva ekologiškam medžio apsauginiam apdorojimui ir yra plačiai naudojamas medžio konstrukcijų apsaugoje, tokiose kaip pastatai, salinės, tiltai ir uostai.

2. Kreozoto taikymas gumenyje pramone :

Į gumos gamyboje kreozotas naudojamas kaip plastifikatorius ir kryžminimo agentas, kuris gali efektyviai pagerinti gumos elastingumą, izlaidingumą ir oksidacijos varžymo gebėjimus. Tai daro jį idealia pasirinkima aukštos reikalavimų gumos produktams, tokiais kaip šoninio gamyba , dengiamieji medžiagos ir kevyklių juostoms .

3. Kiekvieno aliejus vaidmuo denginių ir spalvų pramonėje :

Kaip svarbus šoninio sprendinys denginiuose, jis gali padidinti denginių skysčio ir prisiskverbimo gebėjimus bei pagerinti denginių oro tinkamumą ir UV spindulių išoliaciją. Jis plačiai naudojamas pramonės denginiai, automobilių denginiai ir statybos denginiai , gerinant denginių kokybę ir ilgalaikumą.

4. Inovacinis kiekvieno aliejus taikymas aplinkosaugos srityje :

Su didėjančia aplinkosaugos poreikiu, kiekvieno aliejus yra naudojamas vandens apdorojime ir oro purifikacijoje. Jis gali pašalinti tūriai metalo ionus ir organinių teršalų vandenyje, todėl jis naudojamas pramoniniame šiukšlių vandens apdorojime ir orui išvalymo įrenginiuose , rodant jo aplinkosaugos potencialą.

5. Krioezotas kaip cheminis sintezės surowina:

Krioezotas yra pagrindinė surowinė fenolinių harabalių ir plačiai naudojamas elektrinėse izoliacijos medžiagose, plyve ir statybos medžiagos . Be to, jis taip pat dalyvauja kelių aukštos klasės cheminių junginių sintezėje ir taps svarbiu tarpiniu daugelio pramoninių cheminių junginių .

Iššūkiai, susiję su kriozoto valymu ir šalinimu

Kriozoto šalinimas dažnai yra iššūkis pramoninėse programose, ypač tuo atveju, kai reikalingas efektyvus valymas. Tyrimai rodo, kad skirtingų tipų surfaktantų derinys gali esminiu būdu pagerinti valymo efektyvumą. Pavyzdžiui, derinys iš Triton x-100 (etoksiluoto alkilfenolo surfaktanto) ir Sodio C14-16 olefino sulfonatas (sulfonato surfaktantas) gali sėkmingai emulguoti ir pašalinti kriozotą. Be to, cationinio surfaktanto pridejimas kaip Dodecyltrimethylammonium chloride ne tik stiprina deguonies nuvalymo poveikį, bet ir teikia baktericidinį veiksmą, užtikrinant higieningesnę paviršių po valymo.

Šios inovacinės formulės pritaikymas ne tik padaro kriozoto šalinimą efektyvesniu, bet ir įvertina aplinkos draudimą bei naudojimo saugumą. Ši technologija siūlo patikimesnę ir tvarią sprendimą dėl sunkių aliejynų, pvz., kriozoto, apdorojimo.

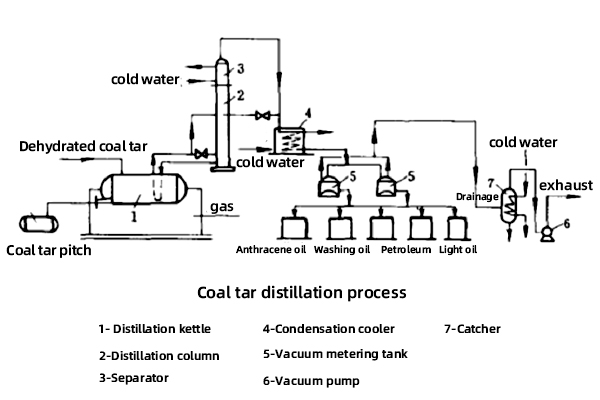

Kriozoto gamybos procesas ir inovacinė technologija

Kreozotas paprastai gaminamas naudojant angikos džiovos destilavimo ir medžio pirólizės technologijas. Su mokslo ir technologijų pažangą gamybos procesas nuolat buvo optimizuojamas, kas padidino kreozoto grąžą ir grynį, tuo pat metu sumažindamas jo poveikis aplinkai. Šiuolaikinė technologija padarė kreozoto gamybą efektyvesne ir leido jį plačiai naudoti pramonėje su aukštesiais reikalavimais.

Neseniais metais žaliosios chemijos konceptas skatina kreozoto taikymą aplinkosaugos technologijoje, pavyzdžiui, jungiant kreozotą su atsinaujinančiomis ištekliais per biodegradacijos technologiją, kad būtų gaminti šviekesni produktai. Ši inovacija ne tik įneša naują gyvybę chemijos gamybai, bet ir skatina tvarų vystymąsi.

Kreozoto sinerginė veikia su kitomis cheminėmis medžiagomis

Kreozotas dažnai vartojamas įvairiose programose, sinergijuojant su kitais chemikalių. Pavyzdžiui, guma produkto gamyboje kreozotas naudojamas kartu su priedais, tokiais kaip vulkanizatoriai, kad pagerinti gumos kryžinius ryšius ir išmokslumą. Tuo pačiu metu, dengos pramoneje kreozotas jungiamas su smoliomis ir spalvomis, kad denginyje būtų aukštesnis prijungimas ir korozijos varžymo išskyrimas.

Su stipresnių aplinkosaugos taisyklių įvedimu, kreozoto ir gamtinių chemikalijų derinys taps vienu iš ateities plėtros krypčių. Kreozoto jungimas su biodegradable medžiagomis ne tik padeda sumažinti išlaidas, bet taip pat sumažina aplinkos taršą ir skatina žaliosios chemijos plėtrą.

Ateities plėtra: žali chemija ir trukmiškos programos

Su besivertinančiu aplinkosaugos sąmoningumu, krekosoto ateitis daugiau kreipsis į žalią chemiją ir tvarumą. Žemesnių anglies dalelių ir mažesnių teršalų gamybos procesai leis krekosotui didesnį poveikį turėti aplinkosaugos srityje. Be to, biologiškai pagrįstų suvesinių naudojimas krekosoto gamybai gana sumažins neigiamą poveikį aplinkai ir taps svarbiu ateities linkiu.

Išvada

Kaip daugiafunkcionalus cheminys medžiagas, krekosotas rodo didelę taikymo potencialą daugelyje sričių. Nuo tradicinių gumo ir spalvų pramonės iki šiandieninės aplinkosaugos ir žemos chemijos sričių, krekosoto naudojimas plėtojas. Su technologijų nuolatiniu tobulėjimu jis turės poveikio daugiau pramonės šakų ir padės pasiekti efektyvesnius ir ramovesnius sprendimus.

Jei jums yra klausimų dėl kreasoto ar kitų cheminių sprendinių, prašome laisvai apsilankyti mūsų svetainėje arba susisiekti su mūsų profesionaliu komanda, mes su džiaugsmu jums padėsime.

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

IW

IW

ID

ID

LV

LV

LT

LT

SR

SR

SK

SK

VI

VI

HU

HU

TH

TH

TR

TR

GA

GA

CY

CY

KA

KA

LA

LA

MN

MN

KK

KK

LB

LB