IBOMA CAS 7534-94-3

שם כימי: איזובורניל מתאקרילט

שמות נוספים: מיאתקרילית אסיד בורנאן-2-יל אסטר

מספר CAS: 7534-94-3

הצורה המולקולרית: C14H22O2

תוכן: ≥99%

משקל מולקולרי: 222.2

EINECS: 231-403-1

מראה: סומק שקוף או צהוב בהיר

- פרמטר

- מוצרים קשורים

- חֲקִירָה

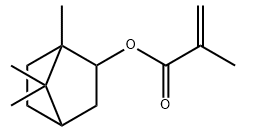

הצורה המבנית:

תיאור המוצר:

| אינדקס | תכונות |

| מראה | שקוף ברור |

| תוכן % ≥ | 98.5 |

| תוכן רטיבות % ≤ | 0.05 |

| ערך חמצן | ≤0.05% (בהתבסס על חומצה מתאקרילית) |

| (MEHQ) תכולת מונע ppm | 90~110 |

| צפיפות | 0.980g/cm3 (20℃) |

| דיסולוביליות | לא פתור במים |

| קשיחות | 10-15(25℃)mPa`s |

| Tg(℃) | 60(מקס) |

תכונות ותכלית:

איזובורניל מתאקרילט הוא מונומר חסר מים, המרכיבים העיקרי שלו הם α-פינן ו-B-פינן. הוא יכול להעניק גמישות למון-מונומר, לשפר את התנגדות המים, התנגדות החום וההתנגד התנגדות האקלים של מערכת הפולימר, ויש לו קשיחות טובה ותנגדות למתה. לכן הוא נחשב למונומר מצוין.

הוא מעניין עבור תרמופלסטיק בגלל תכונות החום הטובות שלו. IBOMA מתאים לרזינות אקריליות ולרזינות כיסוי בדבק עם תרמופלסטיות גבוהה יותר ותכונות תרמוסטטיות טובות יותר. הוא יכול גם לשמש כמתקן דבק ופלסטיק, ולהضافת לכסות UV,หมึก ודבק. הוא יכול גם לשמש כמזהב ריאקטיבי וכמזרק פיגמנטים כדי לשפר קופולימרים. בהתייחס לרזינות אופטית, הוא נמצא בשימוש נרחב בגלל הערך הש-awesome השבר שלו.

מְצִיאוֹת עִטּוּפִים:

המוצר מארז בכדים או בקבוקים, משקל נטו 200 ק"ג, 25 ק"ג כדים פלסטיים אוAINERים של סטainless steal.

במהלך העברה, יש להגן מפני השמש, גשם וטמפרטורה גבוהה.

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

IW

IW

ID

ID

LV

LV

LT

LT

SR

SR

SK

SK

VI

VI

HU

HU

TH

TH

TR

TR

GA

GA

CY

CY

KA

KA

LA

LA

MN

MN

KK

KK

LB

LB