Isopropylfenylfosfat CAS 68937-41-7

Kemisk navn : Isopropylfenyl fosfat

Synonyme navne :IPPP50; Fenol, isopropyleret, fosfat (3:1); Fenolfosfat isopropyleret

CAS-nr :68937-41-7

Molekylær Formel :C27H33O4P

Molekylvægt :452.52

EINECS-nummer :273-066-3

- Parameter

- Relaterede produkter

- Anmodning

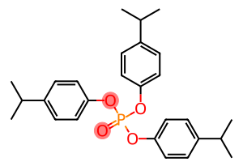

Strukturel formel:

Produktbeskrivelse :

|

Analysebegreber |

Specifikation |

Analyseresultater |

|

Udmeldning,visuel |

Klart gennemsigtigt væske |

Klart gennemsigtigt væske |

|

Hazen farveværdi |

≤ 50 |

42 |

|

Vandeindhold,% |

≤0.1 |

0.037 |

|

Brekningsindex |

1.546-1.555 |

1.549 |

|

Syrevaerd |

≤0.1 |

0.043 |

|

Tab ved opvarmning |

≤0.15 |

0.033 |

|

viskositet |

48-64 |

50 |

|

Tæthed g/ml, 20℃ S.G |

--- |

1.17 |

|

Konklusion |

Kvalificeret |

|

Egenskaber og brug :

Isopropylated Triphenyl Phosphate er et fosfatforbindelse med flammehindrende egenskaber, lav damptryk og fremragende varmebestandighed, og spiller en vigtig rolle i industrielle anvendelser. Som en højtydende tilføjelsesstof bruges IPTPP hovedsagelig inden for plast, gummi, farver, smøremidler og andre områder.

Hovedanvendelsesområder:

1. Flammehæmmende middel:

Plast og gummi: Isopropylfenylfosfat bruges bredt i plast- og gummiprodukter såsom PVC, polyurethan og epoxyresin, hvilket betydeligt forbedrer materialernes flammehæmmende egenskaber.

Ledninger og kabler: Under produktionen af ledninger og kabler fungerer IPTPP som flammehæmmende middel for at sikre materialens stabilitet og sikkerhed under høj temperatur og elektriske fejl.

2. Plasticiserende stof:

PVC-produkter: Som plastificeringsmiddel kan Isopropylphenyl fosfat forbedre fleksibiliteten og bearbejdningsegenskaberne af PVC og bruges bredt i fremstillingen af kabelskiver, filmer, rør og gulvematerialer.

Gummiprodukter: I gummiindustrien forbedrer IPTPP ikke kun gummiets bearbejdningsydelse, men forbedrer også dets slipmodstand og vejrtrælighed.

3. Smøremidleradditiver:

Industrielle smøremidler: kan bruges som tilføjelsesstof til smøremidler, især under høj temperatur og høj trykforhold, for at forbedre oxidationstræligheden og slipmodstanden af smøremidlerne og udvide udstyrets levetid.

4. Beklædninger og limmidler:

Beklædninger: I beklædningssammensætninger kan det forbedre kemisk modstandsdygtighed og holdbarhed af beklædninger samtidig med at forbedre korrosionsresistensen.

Lim: I limformlen forbedres limets fleksibilitet og sæthedsevne.

Opbevaringsbetingelser: Undgå kontakt med ild og gem på et køligt, tørt sted.

Pakning: Dette produkt er pakket i tromler på 25kg, 100kg, 200kg, og det kan også tilpasses efter kundens krav

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

IW

IW

ID

ID

LV

LV

LT

LT

SR

SR

SK

SK

VI

VI

HU

HU

TH

TH

TR

TR

GA

GA

CY

CY

KA

KA

LA

LA

MN

MN

KK

KK

LB

LB