Гидроксид алуминий: екологично безопасен противопожарен агент, водещ зелената индустриална революция

През последните години, гидроксид алуминий (21645-51-2) , като материал с екологични характеристики и функционално разнообразие, играе все по-важна роля на глобалния пазар.

Този бял праховиден неорганичен противопожарен агент е бил широко използван в много области поради своите свойства като противопожарен, подаване на дим, напълване и други, както и поради своите екологични предимства на химическа инертност, нетоксичност и липса на вторично замърсяване, и е станал "главната сила" сред неорганичните противопожарни агенти.

Данни показват, че потреблението на хидроксид алуминиев е се повишило над 80% от общото потребление на неорганични противопожарни агенти, а това рязко нарастване на заявкта стимулира пазара да влезе в вълна от технологично иновиране и индустриално оновяване.

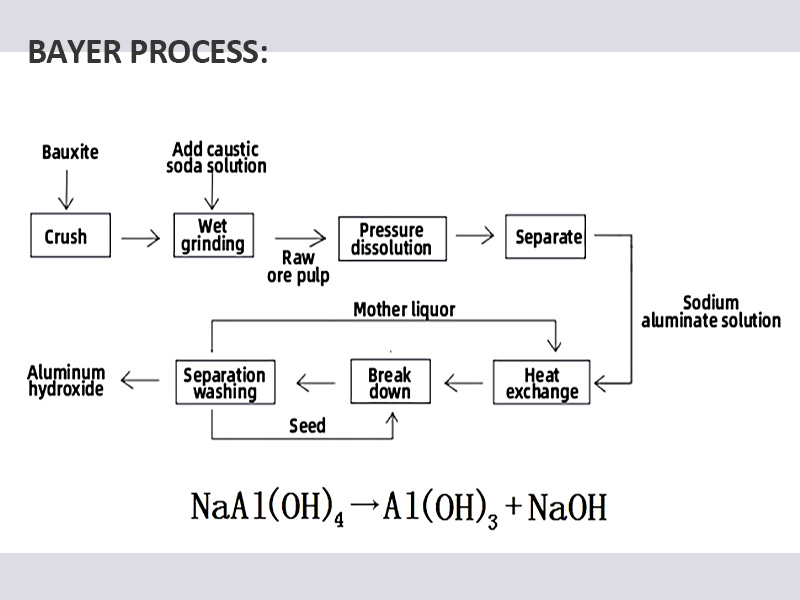

Байєровият метод: незаменима производствена технология в modenата индустрия

Байєровият метод е класически процес за производство на алумина от боксит, който играе ключова роля при големомащабното производство на хидроксид алуминиев.

Този процес постига ефикасно извличане и рециклиране чрез две основни реакции: първо, реакцията на дисолюция при висока температура и притиск, която реагира алюминиевата окисъл в бокситите с концентрирана хидроксидова сода, за да се генерира разтворим алюминиев содов сол; след това, чрез охлаждане, разредяване и добавяне на семена от алюминиев hidroksid, се започва декомпозиционна реакция, която декомпонира содовия алюминиев сол до алюминиев hidroksid. Тази технология не само постига производството на високочист алюминиев hidroksid, но също така подобрява употребата на ресурси и намалява екологичната тежест на индустриалното производство чрез рециклирането на хидроксидова содова смес.

Многоотраселово изискване: насърчаване на материална иновация и персонализирано развитие

С бързото нарастване на глобалния спрос за екологично чисти пламенно-сдържливи материали, различните индустрии предявиха още по-разнообразни и специфични изисквания към характеристиките на хидроксид алуминий. Тези изисквания не само стимулират разширяването на пазара, но и подпомагат непрекъснатото оптимизиране на технологиите и приложенията на хидроксид алуминий.

1. Материал от EVA пен: ключови са високата чистота и стабилност

Материалът от EVA пен се използва широко в интериорното оздобление и обществените места, като има изключително високи изисквания към пламенно-сдържливите свойства.

Добавянето на хидроксид алуминий в областта на материалите от EVA пен може да достигне до 60%, затова е необходимо да се гарантира изключително висока чистота и стабилна pH стойност, за да се отговаря на строгите пламенно-сдържливи стандарти на тази индустрия. Този спрос е подтикнал непрекъснатото обновяване на производствените процеси, за да се гарантира, че плевелните материали ще поддържат отлични характеристики дори в приложението високоинтензивни условия.

2. Продукти от силиконов каучук: двойно равновесие между функция и механични свойства

Силиконовият каучук е още една важна област на приложение на хидроксид алуминий.

За да се удовлетвори заявк търсенето за високопроизводителни противопожарни добавки в индустрията на силиконовия каучук, хидроксид алуминий обикновено трябва първо да бъде повърхностно обработен с силан, а разпределението и чистотата на неговите частици трябва да бъдат строго контролирани. Това не само подобрява свързването между противопожарната добавка и силиконовият каучук, но също така има предвид механичните свойства на материалa, гарантирайки по-добро равновесие между напълването и противопожарната защита.

3. Инкзи и покрития: важността на цвета и стабилността на дисперсията

В производството на индустриите за инкзи и покрития има изключително строги изисквания към белизнатостта, усвояването на масло и дисперсионните свойства на хидроксид алуминий.

Противопожарните добавки от хидроксид алуминий трябва да имат ниско усвояване на масло, за да се гарантират ефектите при печатане и покриване.

Пламенно-тормозните агенти от алуминиев hidroksid трябва да са без примеси и да имат висока бялчина, за да се гарантира чистотата и цветът на тънкостените и лаковете.

Качествените пламенно-тормозни агенти от алуминиев hidroksid не трябва да се осадяват в тънкостените и лаковете, за да се поддържа техната стабилност и равномерност.

4. Материали TPU/TPE: Микроново ниво на точен контрол подобрява характеристиките

В областта TPU и TPE, алуминиев hidroksid не само трябва да има микроново разпределение на частиците, размерът на частиците му трябва да е под 2.0 мика и разпределението на частиците трябва да е равно, но също така трябва да бъде повърхностно активирано, за да се усилить свързващата сила му с други вещества, докато се подобрява процесната текливост на алуминиев hidroksid, за да може да бъде по-равномерно разпределен в материалите, по този начин постигайки добър пламенно-тормозен ефект.

Този метод за усъвшене не само значително подобрява ефекта на огнестойкостта на материалите, но и повишава съпротивността на износ и раздиране, правейки го по-конкурентен в областта на функционалните материали.

5. Дръжки и кабели: надеждни стражи на пожарната безопасност

Промишлеността на дръжките и кабелите има особено строги изисквания за огнестойките материали. Алуминиев hidroksid се е превърнал в важна част от индустрията с отличната си огнестойкост, топлостойкост и продължителна стабилност.

Не само че алуминиевият hidroksid огнестойкост трябва да има висока огнестойкост, за да гарантира безопасността на дръжките и кабелите при пожари.

Трябва също така алуминиев hidroksid огнестойкост да запази стабилността и продължителността си по време на производството и употребата на дръжките и кабелите, без да влияе на характеристиките и срока на служебна годност на дръжките и кабелите.

Засилващата защитна ефективност на алуминиев hidroksid в условията на високи температури позволява жиците и кабелите да предоставят повече време за избягване при пожари, което подобрява общата безопасност.

Пазарни перспективи: Тенденциите за защита на околната среда държат индустриалното обновяване

При все по-голямата глобална търсеност за зелени материали, пазарът на алуминиев hidroksid се намира пред небивални възможности за развитие.

С единия ъгъл, все по-строгите правила за защита на околната среда са задължили компании да се преобразуват към по-екологични и с по-висока производителност материали; с другия ъгъл, непрекъснатото иновиране на технологиите за алуминиев hidroksid отваря също така вратите за неговото приложение в нови области като материалите за нова енергия и висококачествените композитни материали.

Експертите прогнозират, че пазарът на алуминиев hidroksid ще продължи да се движи към по-висока производителност, специализация и интелигентност в бъдеще, още повече разширявайки своето влияние на световния пазар за противопожарни материали.

Резюме: Многосилови фактори формират новата ера на хидроксид алуминий

От технологичното иновиране на процеса Байър до персонализираното развитие на нуждите на много индустрии, промишлената стойност на хидроксид алуминий се изследва и умножава постоянно.

Той не само е основният стълб на настоящия пазар на противопожарни материали, но също така е важен двигател за развитието на зелената химикална индустрия.

В бъдеще, с координираното развитие на технологията и пазара, този екологичен материал ще продължи да води глобалния пазар на противопожарни материали в новата ера на устойчивото развитие с неговите уникални предимства.

Ако имате нужда да закупите хидроксид алуминий, моля, свържете се свободно с нас

Други преимуществени продукти на нашата фабрика:

Флуоресцентно осветляващо вещество 378 CAS 40470-68-6

Eтилмагнезиев Бромид CAS 925-90-6

Натриев етилоксид CAS 141-52-6

2,5-ДИМЕТОКСИ-БЕТА-НИТРОСТИРЕН CAS 40276-11-7

ХРОМ(III) ФОСФАТ CAS 7789-04-0

PETMP CAS 7575-23-7

4-tert-Бутилбензойна киселина CAS 98-73-7

Irgacure 819 Фотоинициатор 819 CAS 162881-26-7

Хидротальцит CAS 11097-59-9

POLY(HEXAMETHYLENE DIISOCYANATE) CAS 28182-81-2

BISPHENOL A DIGLYCIDYL ETHER RESIN CAS 1675-54-3

Гликолна киселина CAS 79-14-1 (99% прах или 70% решение)

Азобисизобутиронитрил (AIBN) CAS 78-67-1

Глиоксал CAS 107-22-2

НАТИСНЕТЕ ЗА ДА ОТИДЕТЕ НА СТРАНИЦАТА ЗА ПРОДУКТИ

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

IW

IW

ID

ID

LV

LV

LT

LT

SR

SR

SK

SK

VI

VI

HU

HU

TH

TH

TR

TR

GA

GA

CY

CY

KA

KA

LA

LA

MN

MN

KK

KK

LB

LB